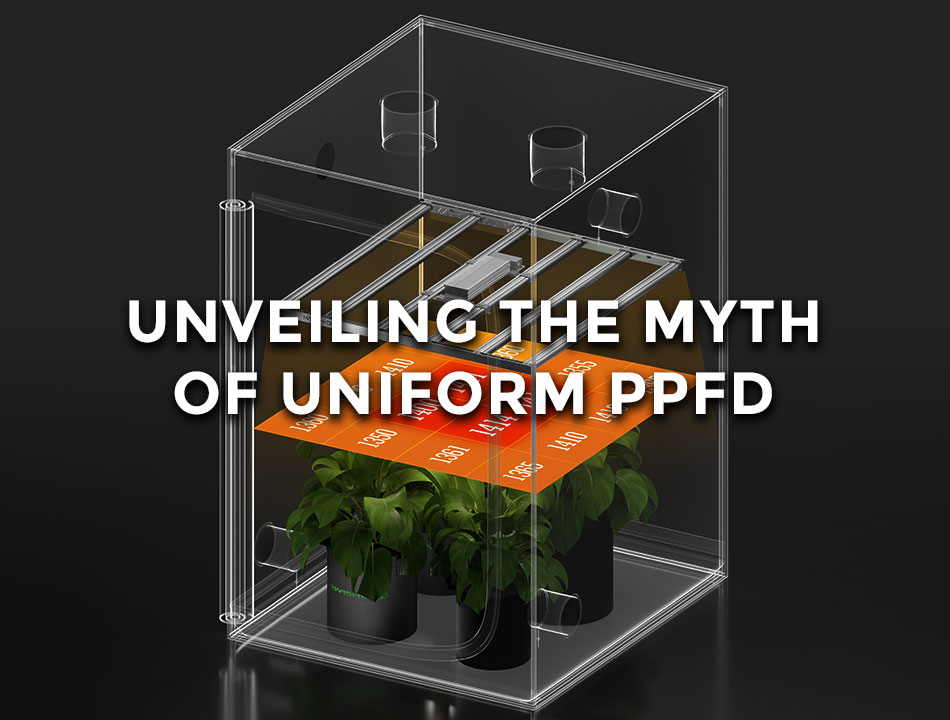

In the intricate world of plant cultivation, particularly within controlled environments like grow tents, understanding the nuances of light exposure is crucial. PPFD, or Photosynthetic Photon Flux Density, stands at the forefront of this understanding, directly influencing plant growth and vitality. However, a common misconception lingers among many growers about the need for uniform PPFD – a concept that, while seemingly logical, doesn’t always align with the complex reality of plant needs.

Understanding PPFD and Plant Growth

What Is PPFD?

PPFD, or Photosynthetic Photon Flux Density, is a measure that is essential in understanding how light affects plant growth, particularly in controlled environments like indoor gardening or greenhouse cultivation.

Here's a breakdown of what PPFD means:

-

Photosynthetic: This term relates to photosynthesis, the process by which plants use light to create energy. It's the foundation of a plant's ability to grow and produce oxygen.

-

Photon: Photons are particles of light. In the context of PPFD, we're particularly interested in photons within the specific range of light wavelengths that plants can use for photosynthesis, usually between 400 and 700 nanometers (the visible spectrum).

-

Flux: This term refers to the flow or rate of delivery of these photons to the plant's surface.

-

Density: This indicates the concentration of photons in a specific area, typically measured in micromoles per square meter per second (µmol/m²/s).

In simpler terms, PPFD measures the amount of usable light (in the form of photons) that reaches a given area (like a plant's leaves) each second. This measurement is crucial for understanding how much light a plant receives for photosynthesis, which in turn affects its growth, health, and yield. Different plants have different PPFD requirements depending on their stage of growth and the specific conditions they thrive in.

Plant Requirements

Different plants have diverse light needs, and this is where understanding PPFD becomes especially important. Not all plants are created equal when it comes to their requirements for light, and these needs can vary significantly depending on a variety of factors, including the plant's species, stage of growth, and the specific conditions under which it thrives. Even different parts of the plant may require varied light intensities. For instance, leaves are primary sites for photosynthesis, so they typically require higher light levels. However, flowering and fruiting may demand different light conditions, and roots may require minimal light exposure.

For example, plants like lettuce, herbs, and other leafy greens generally require lower PPFD levels. They can thrive under moderate light intensity, making them suitable for indoor environments where light conditions are not extremely high. On the other hand, plants such as tomatoes, peppers, and weed often demand much higher PPFD values to reach their full growth potential. These plants typically need more intense light to support their development, particularly during the flowering and fruit-bearing stages.

PPFD Requirements for Different Growth Stages

PPFD requirements vary significantly depending on the growth stage of plant. If you want to explore plant growth intricacies, click here for a close-up view of PPFD.

PPFD for Seedlings

For seedlings, the PPFD requirements are relatively low compared to more mature stages of plant growth. Seedlings are delicate and their photosynthetic machinery is still developing, making them sensitive to intense light. Exposing them to too high a PPFD can lead to stress, leaf burn, or stunted growth.

For most seedlings, a PPFD of approximately 100-300 µmol/m²/s is suitable. This range provides enough light for healthy growth without the risk of damaging the young plants.

PPFD for Vegetative Stage

During the vegetative stage, plants require more light than in the seedling stage, as they are actively growing leaves and stems. The PPFD levels during this phase are crucial for developing a strong and healthy structure that can support flowering and fruiting later on.

For the vegetative stage, a PPFD of about 600-1,000 µmol/m²/s is typically recommended. This range encourages healthy leaf and stem growth without overstressing the plants.

The exact PPFD within this range can vary depending on the type of plant. Some plants, especially those native to sunnier climates or those that will eventually bear fruit, may benefit from the higher end of this range.

PPFD for Flowering Stage

The flowering stage is a critical period in a plant's life cycle, and the PPFD requirements are significantly higher compared to the vegetative stage. During flowering, plants are developing buds, flowers, or fruits, and require ample light to support this energy-intensive process.

For most weed plants, a PPFD between 1,000-1,200 µmol/m²/s is ideal during the flowering stage. This increased light intensity supports the development of flowers and fruits. Some plants, particularly those that are high-light species, can benefit from even higher PPFD levels, sometimes exceeding 1,200 µmol/m²/s. However, this is contingent on other growth conditions being optimal, including temperature, humidity, CO2 levels, and nutrient availability. To explore more, we also have a guide to using CO2 to increase yield for you.

Is Uniform PPFD Always Necessary?

The notion that uniform PPFD is essential for successful plant cultivation is not a one-size-fits-all rule, especially when considering the complex nature of plant biology and the varied aspects of cultivation practices. While uniform PPFD, which ensures consistent light intensity across a growing area, might be significant in certain commercial operations focused on monoculture, its importance diminishes in other contexts, particularly for individual and hobbyist growers.

For Individual Growers

Uniform production in commercial operations is pivotal for ensuring consistency in product quality. Each plant receiving similar growing conditions leads to a uniform crop, crucial for maintaining marketability in terms of size, flavor, potency, or other characteristics. This uniformity is not just about product quality; it extends to yield predictability, an essential factor for business planning and meeting market demands.

In contrast, individual growers often have different priorities. For these growers, the focus might be more on the experience of growing, personal use, or the quality of a few plants rather than on maximizing output. Their hands-on approach, where they can closely monitor and care for each plant, allows them to compensate for non-uniform PPFD effectively. By making adjustments based on each plant’s response to light, they can achieve their desired cultivation goals without the need for uniformity.

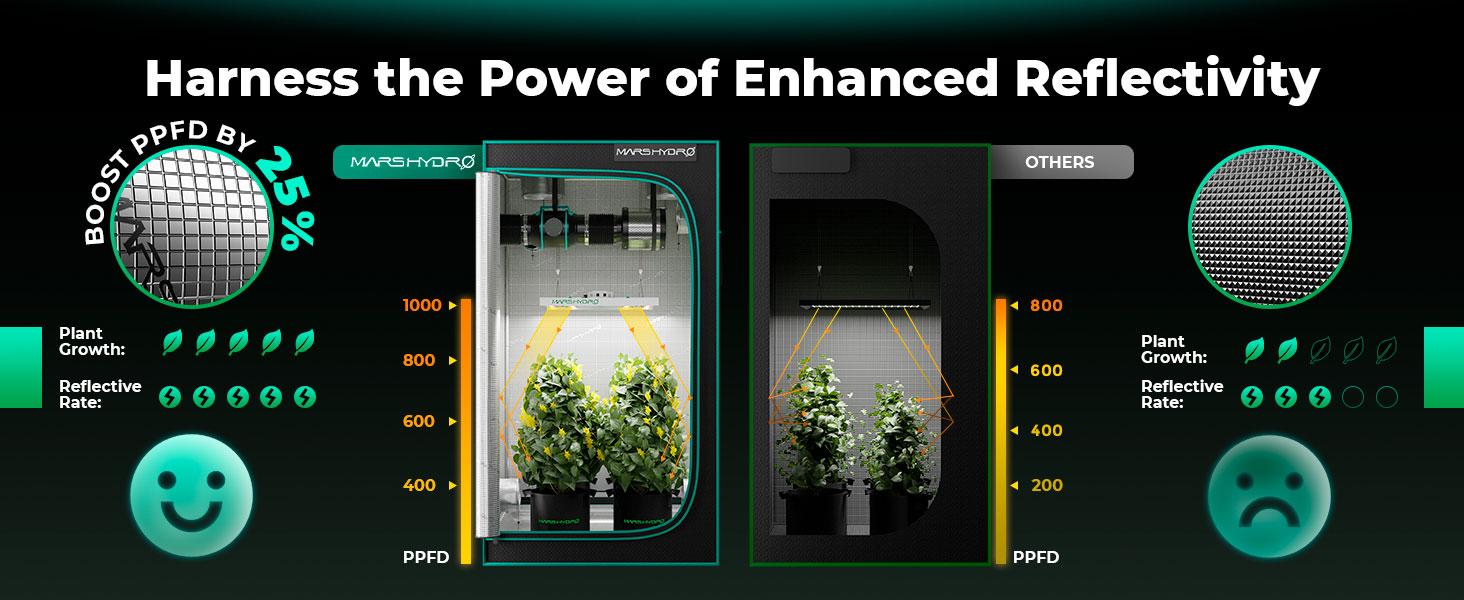

Mylar: The Key to Efficient and Sufficient PPFD Output

The use of Mylar in grow tents is another primary reason why individual weed growers do not require uniform PPFD. Its ability to efficiently manage light, cater to plant needs, and provide cost-effective solutions aligns perfectly with the objectives and constraints of individual growers, offering them a flexible and efficient approach to plant cultivation.

Mylar’s ability to reflect and redistribute light effectively counters the need for PPFD across the entire grow space. By redirecting light to areas that might otherwise receive lower intensity, Mylar ensures that all parts of the plant get the light they need. This is particularly beneficial for individual growers who may have diverse plant types in a single space, each with its own light requirements. The reflected light from Mylar means that plants situated in less directly lit areas still receive adequate light, reducing the need for a uniform light intensity throughout the grow tent.

By reflecting light that would otherwise be lost, mylar effectively increases the PPFD that reaches the plants. This reflective enhancement means that the actual PPFD experienced by the plants is often higher than the initial emission from the light source. It allows growers to focus light where it's most needed without having to maintain high-intensity lighting uniformly across the grow area. This not only leads to more robust growth and potentially higher yields but also means that growers can cater to the specific needs of different plant parts or various plant species within the same space.

Additionally, Mylar minimizes drastic variations in light intensity within the grow tent. While achieving completely uniform PPFD is not the goal for many individual growers, Mylar's ability to even out light distribution ensures that no plant part remains in deep shade. This contributes to more balanced growth across the entire plant, a benefit that can be particularly advantageous in a diverse growing environment.

In terms of cost and environmental impact, Mylar stands out as a practical solution for individual growers. Its capability to maximize the efficiency of existing light sources translates into significant cost savings and a reduced environmental footprint. Growers can achieve the desired light intensity for their plants without the need for additional lighting systems, which is an attractive proposition for those mindful of their energy consumption and operational costs.

Higher PPFD: Elevating Flowering Stage Efficiency

The requirement for high PPFD levels, particularly over 1100 µmol/m²/s during the flowering stage of weed plants cultivation, is a significant factor in why individual growers do not rely on uniform PPFD of their LED grow lights.

Individual growers often position their plants in the center of the grow tent. During the flowering stage, a critical phase, weed plants benefit significantly from a PPFD that exceeds 1100 µmol/m²/s. This intense light concentration in the tent's central area is essential for optimizing flower development, enhancing the plant's growth rate, and improving overall yield quality.

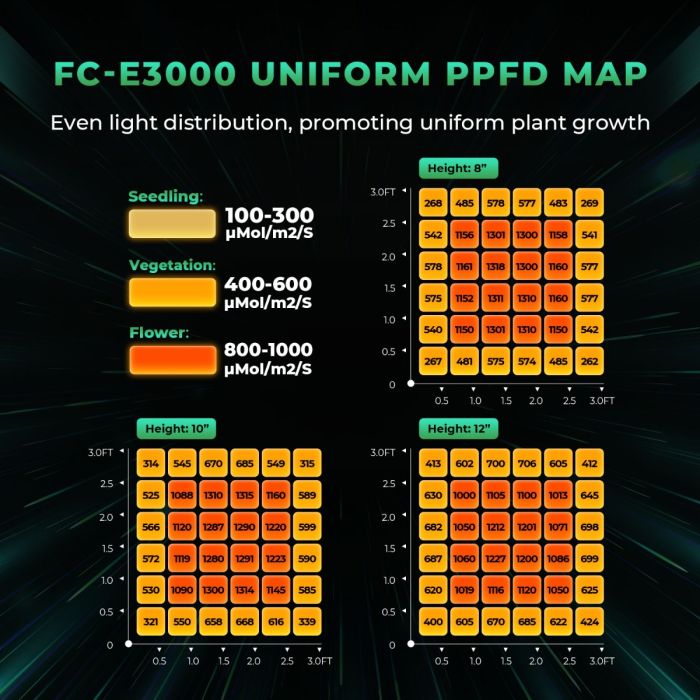

| Product | Wattage | Max PPFD | Warranty | Price |

| FC-E3000 | 300w | 1314 | 5 years | US$249.99 |

| Brand X | 320w | 1000 | 3 years | US$339.99 |

The data provided in the table compares two LED grow lights, the FC-E3000 and Brand X, based on several parameters including wattage, max PPFD, warranty, and price.

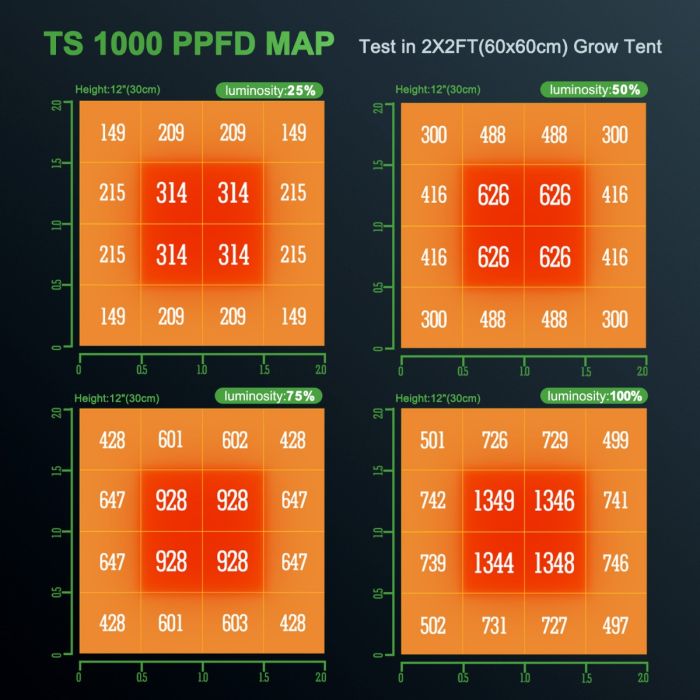

Displayed are PPFD maps for our FC-E3000 and Brand X's KS3000 LED grow lights. Each map shows the specific PPFD values at given distances for different growth stages: seeding, vegetative, and flowering.

Based on the information in the images, our FC-E3000 LED grow lights outperform Brand X's LEDs by satisfying the higher PPFD needs, delivering more than 1100 µmol/m²/s for the flowering stage. With the addition of advanced red and blue light spectrums, they substantially boost yield outcomes. This capability sets the FC-E3000 apart from other products in the market, which generally only support a PPFD of around 1000 µmol/m²/s. The higher PPFD output of our LED grow light ensures that the plants receive the intense light needed for effective flowering, something that cannot be guaranteed with lower-intensity lighting solutions like Brand X, even though it has a higher wattage and price.

In conclusion, uniform PPFD plays a role in commercial plant cultivation, ensuring consistent quality and yield. However, for individual growers, a uniform PPFD is less essential due to their unique needs. Utilizing Mylar in grow tents offers an efficient and cost-effective way to manage light distribution. When combined with the strategic use of high-intensity lighting, particularly during vital growth stages like flowering, individual growers can effectively meet the specific needs of their plants. This approach leads to healthy plant growth and optimal yields in their cultivation experience.

Final Thoughts

It's clear that the necessity for uniform PPFD in plant cultivation is not an universal rule, especially for individual growers. Their unique cultivation scenarios, varying plant requirements, and the adaptive use of grow tents illustrate that successful growth can be achieved through more personalized and flexible lighting strategies. Uniform PPFD, while beneficial in certain contexts, is not an absolute requirement for all.