As modern agriculture and horticulture continue to evolve, so do the technologies that support them. Among these innovations, the rise of LED

grow lights has sparked a transformation in indoor cultivation practices. LED grow lights offer growers an array of advantages, from precise spectrum control to longer lifespans. Yet, as with any technological advancement, questions arise, and one of the most pressing is whether LED grow lights are truly cost-effective when it comes to electricity consumption.

So, let's shine a light on the subject of LED grow light electricity cost and answer the question: Are these lights cost-effective for modern indoor growing endeavors?

How to Judge Whether an LED Grow Light Is Cost-Effective?

Check Your Light Wattage

LED grow lights with lower wattage ratings are typically more cost-effective because they consume less electricity while still delivering the essential light spectrum for plant growth. These energy-efficient lights not only reduce ongoing electrical expenses but also exhibit longer lifespans, minimizing replacement and maintenance costs.

The wattage of LED grow lights plays a significant role in determining their cost performance, especially when considering lights with the same coverage area. To illustrate this, let's examine two scenarios with different wattage LED grow lights covering the same 4'x4' area.

Scenario 1: A 650W LED Grow Light

This light consumes 650 watts of electricity per hour.

Assuming it operates for 12 hours a day, the daily energy consumption is650W x 12 hours = 7.8 kWh.

At an electricity rate of $0.12 per kWh, the daily cost is$0.12 x 7.8 kWh = $0.94.

Over a month (30 days), the cost would be$0.94 x 30 = $28.2.

Scenario 2: A 800W LED Grow Light

This light consumes 800 watts of electricity per hour.

Operating for 12 hours daily, it consumes800W x 12 hours = 9.6 kWh per day.

At the same electricity rate, the daily cost is$0.12 x 9.6 kWh = $1.15.

Over a month, this amounts to$1.15 x 30 = $34.5.

Comparing the two scenarios, the 650W LED grow light costs significantly less to operate over a month, saving nearly half of the electricity costs compared to the 800W light while providing equivalent coverage.

Just referring to wattage, within the same coverage area, plant lights with lower wattage generally have lower prices, lower electricity expenses, lower planting costs, and higher cost performance. The higher the wattage, the higher the electricity bill. But you don’t want your grow lights to be too weak, and there are many grow lights on the market that aren’t strong enough, so be careful when buying. Try to find grow lights that will provide enough light for your indoor plants without increasing your expenses. However, when you judge whether an LED is cost-effective, you also need to refer to its design, performance and other factors except for its wattage.

Uniform PPFD Value or Not

The relationship between uniform PPFD and the cost-effectiveness of LED grow lights is integral to achieving optimal indoor cultivation results while keeping operational expenses in check. So whether an LED grow light can provide enough light for plants at every stage of their growth is also the standard for testing the quality of them.

Comparing some LED grow lights with similar PPFD values, some of them have lower PPFD values on their edge. And in order to provide enough light to all corners of the coverage area, these lights need to increase the lumiosity. However, some grow lights with relatively uniform PPFD values do not need it.

As is known to all, plant growth generally goes through three stages - seedling stage, growth stage and flowering stage. Taking weed as an example, the PPFD value required for the seedling stage is about 100-300 µMol/m2/S; for the vegetation stage is about 400-600 µMol/m2 /S, and for the flowering stage is about 800-1,000 µMol/m2/S.

To better illustrate this to you, we collected some data. According to some data, brand A grow lights provide uniform PPFD. And each position within the coverage area can receive relatively average light. There will be no hot spots in the center, and the PPFD value in the corners can also reach about 400µMol/m2/S. Brand B grow lights provide uneven PPFD value. And the PPFD value in the corners of the coverage area is only about 200µMol/m2/S. Hot spots appear in the center, which can easily burn the plants.

Taking the seedling stage as an example, the luminosity of Brand A is 25%. However, in order to ensure that the corners of the coverage area receive sufficient lighting, the luminosity of Brand B may be required to set to 50%, which also increases the electricity bill and the cost of planting.

In this comparison, LED A emerges as the more cost-effective choice. Its uniform PPFD distribution ensures that all corners within the coverage area receive consistent and adequate light for optimal growth. In addition, it can also reduce electricity bills and achieve maximum output with the lowest expenditure.

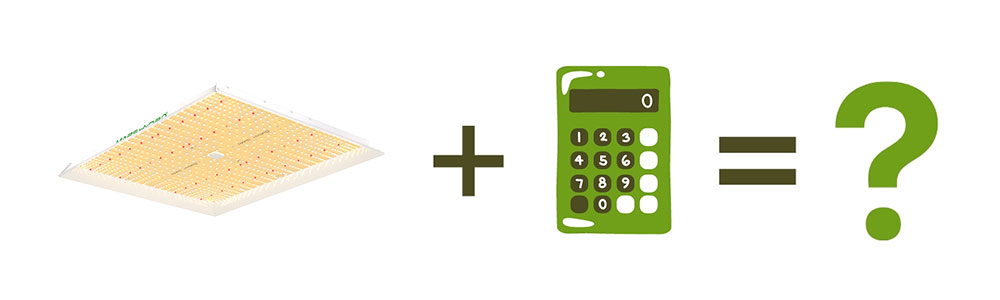

Use Formula to Calculate

To get a really accurate idea of what your electricity bill will be when you introduce grow lights in your growing, you can use the Grow Light Cost-Effectiveness Calculator. By entering some simple information, you can find out how cost-effective your grow lights are (how much it costs to grow a gram of weed) in a short time. It gives you a realistic expectation of the cost of using grow lights for your indoor plants.

First, to calculate the cost-effectiveness of your LED grow lights, you need to collect a few data:

- Electricity cost per cycle($)

- LED grow light cost($)

- Benchmark harvest(PPF value/0.5)

The basic principle for calculating the cost-effectiveness of LEDs is to divide the sum of electricity bill and grow light costs by the yield to get the cost per gram of weed grown. And the smaller the final calculated value, the more cost-effective your LED grow light will be.

Formula: Cost performance ($/g)= (Electricity cost per cycle+ LED cost) / total output

For example: ($84.56+$249.99)/416g=$0.8/g

Here, we compare the Mars Hydro FC-E1000W grow light with several popular LED grow lights on the market with similar power draw and PPF values, and calculate their cost performance for your reference.

Brand | LED Cost ($) | Power Draw (W) | PPF Value (umol/S) | Benchmark Harvest (g) | Electricity Cost per Cycle ($) | Cost Efficiency ($/g) |

Mars Hydro | 819.99 | 900 | 2766 | 1383 | 253.69 | 0.78 |

A | 1299 | 1000 | 2900 | 1450 | 281.88 | 1.09 |

B | 1299 | 1050 | 2470 | 1235 | 295.97 | 1.29 |

According to the data calculated in the above table, Mars Hydro FC-E1000W has the lowest Cost efficiency value, which means that this grow light has the highest cost performance compared to the other two. In addition to FC-E1000W LED grow lights, we also selected several Mars Hydro LEDs to compare with lights from other brands on the market. The comparison results show that the following grow lights are the most cost-effective, they are FC-E3000, FC3000, TSW2000, FC-E4800, FC4800, TS3000, FC-E6500, FC6500.

Final Thoughts

In a world that is becoming increasingly aware of energy consumption, LED grow lights represent a cost-effective solution. And in the above content, we have provided you with some methods to judge whether an LED grow light is cost-effective. If you have any other question about how to choose a cost-effective grow light, please feel free to contact us and we will provide you with solutions as soon as possible.